2025 ROCKY MOUNTAIN CHAPTER AVS SYMPOSIUM

Thursday, November 6, 2025

DoubleTree by Hilton Hotel – Westminster, CO

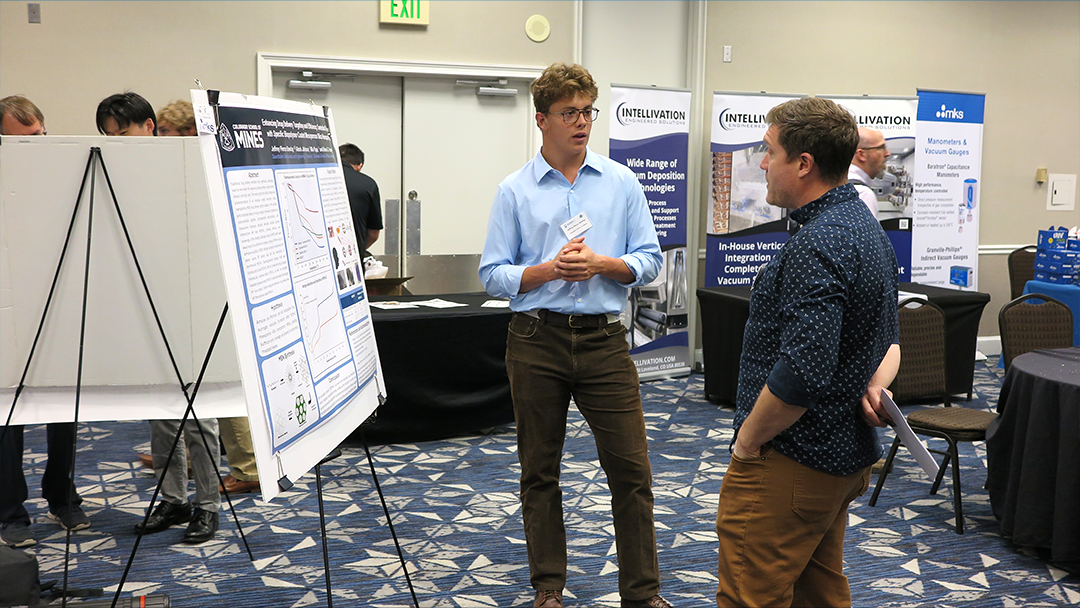

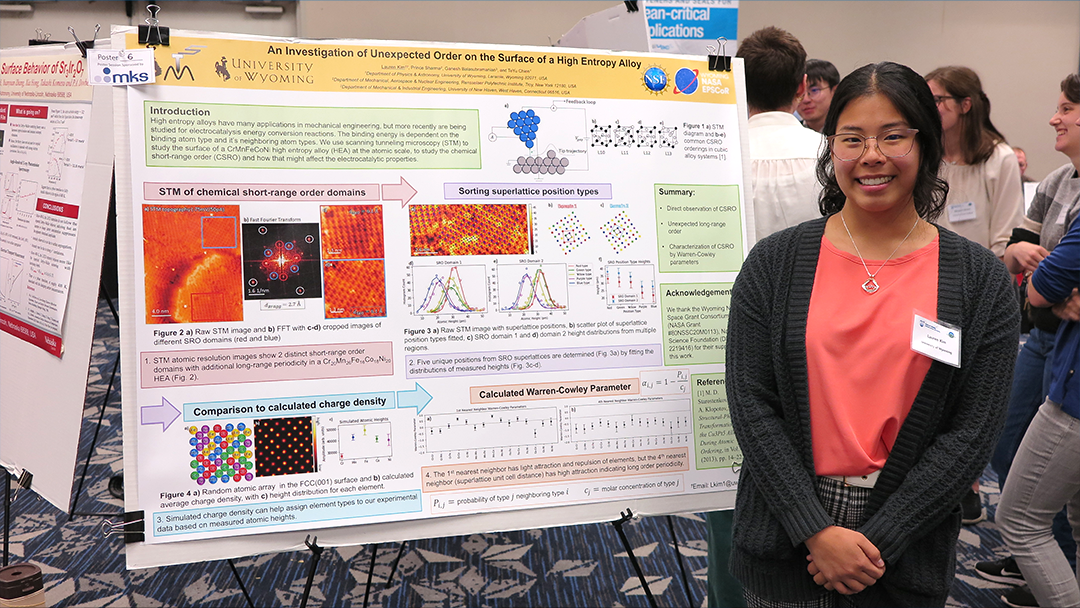

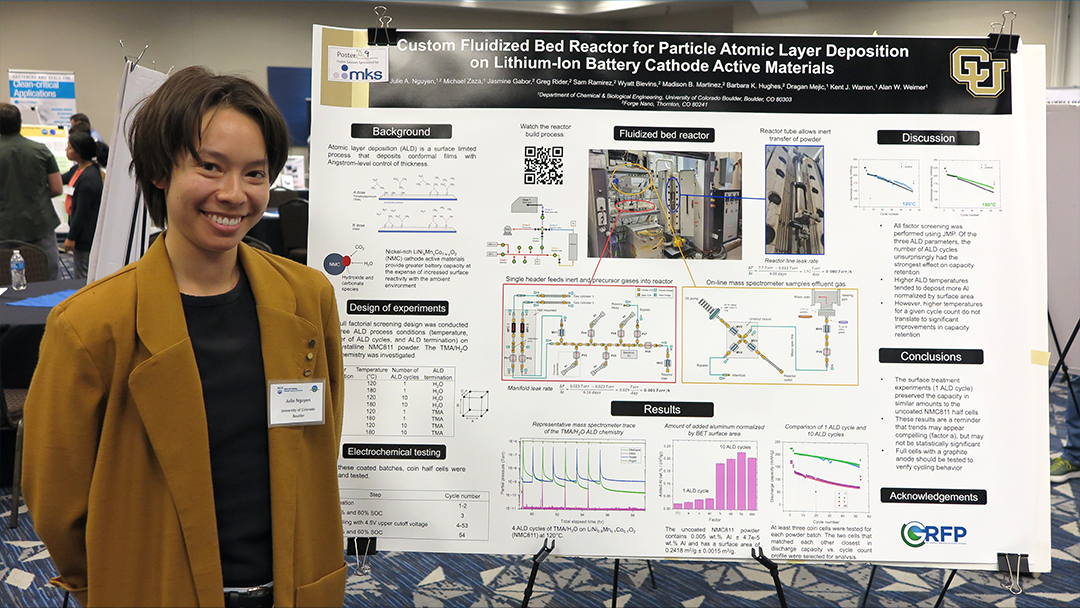

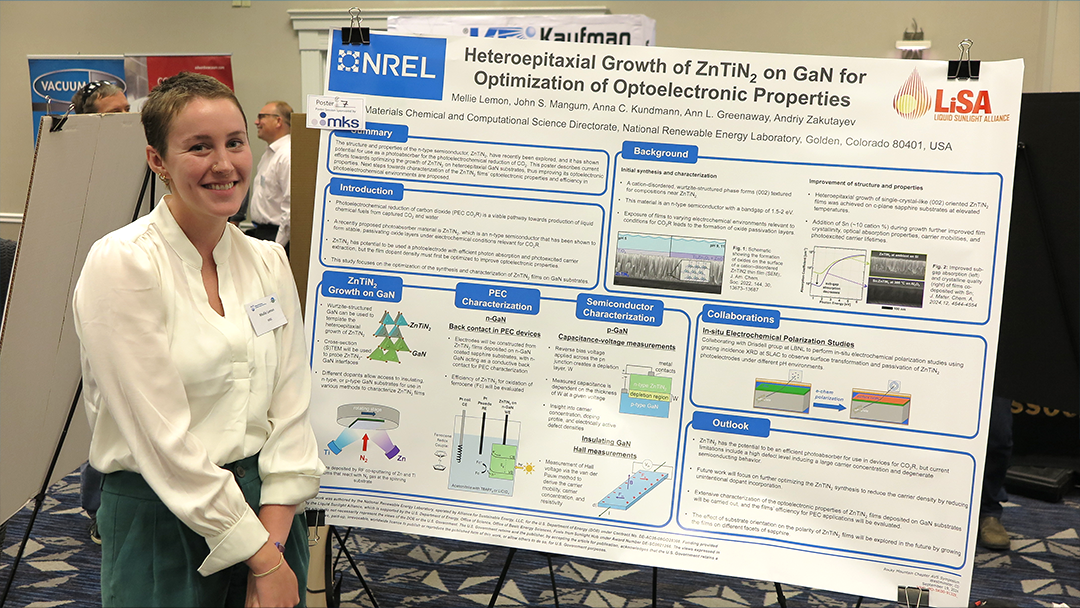

The Rocky Mountain Chapter of AVS is very pleased to announce that we will be having our Annual Symposium on Thursday, November 6, 2025. We will have vendor exhibits from 10 a.m. to 6 p.m. In the morning we have a free half-day class and talks (see schedule below). Lunch is free with registration. You can join us in the afternoon for more talks, a student poster session, and a networking hour with a selection of free food and beverages, plus prizes :-).

Please mark your calendar, register for free, and plan to attend. Updates will be posted below as planning progresses, so do check back.

Symposium

& Vendor Exhibit Nov 6

Student Posters

& Awards Nov 6

Short Courses Nov 5-7

2025 Annual Symposium & Equipment Exhibit Program

Schedule

Hidden

9:00 - 9:40 am | Advanced Manufacturing & Technology for Vacuum Web Coating Systems | Mark George, Intellivation

The global demand for high-performance vacuum coating solutions continues to rise, driven by advancements in optics, electronics, aerospace and energy applications. This presentation explores how engineering excellence fuels growth in vacuum coating technologies through strategic vertical integration, robust in-house engineering, technical process capabilities, advanced automation, and strong collaboration with suppliers. By consolidating design, manufacturing, and process development under one roof, we can accelerate innovation cycles, reduce lead times, and maintain tighter quality control. Supplier partnerships further enhance agility, sustainability, and responsive scaling in diverse markets. Together, these integrated approaches position vacuum coating manufacturers to meet evolving global standards while fostering regional economic development and technical resilience. In-house process development has enabled rapid prototyping and scalability for using flexible vacuum coating solutions into manufacturing production.

9:40 - 10:10 am | Advanced Cryogenic Needs for Quantum Science (i.e., Dilution Refrigeration) | Tim Gessert, Gessert Consulting

The AVS has provided various types of education opportunities since the mid 1960’s. These have included public and private short courses for working technologists, training for high-school teachers through the AVS Science Educators Workshop (SEW), as well as on-line webinars and You-Tube videos available to the general public through the avs.org website. Most recently, a project funded through the American Institute of Physics (AIP) has allowed the AVS to explore expanding these education opportunities to communities historically underrepresented in high-technology sectors.

In an effort to address another important educational request, the AVS has begun to consider how to provide educational content for the rapidly expanding area of Quantum Science. Although many of the skills required for quantum technology are consistent with those of the present electronics industry, the cryogenic needs are markedly different. This talk will describe present efforts to develop AVS Short Course content that would provide technologists in the field of quantum technology with a “basic understanding” of cryogenic dilution-refrigeration systems. These refrigeration systems are necessary to maintain quantum “qubits” at temperatures of a few milli-Kelvins during operation of quantum computers. To expedite the development of this course content, it is believed that elements of the existing AVS courses can provide critical technology foundations, thereby enabling quantum-cryogenic equipment to be more readily understood by course participants (e.g., pulse-tube and Helium-dilution refrigerators). This initial course content is expected to expand over time to include other topics of increasing interest to the quantum workforce, such as content related to operation and maintenance of these very low temperature cryogenic systems.

10:20 - 10:50 a.m. | Coffee Break and Vendor Exhibits

10:50 - 11:30 am | A Collaborative, Analytical, Data-driven Approach to CdTe Thin Film Development | Cullin Wible, The Conti Group

The Conti Innovation Center is focused on advancing cadmium telluride thin-film technologies for solar applications through collaborative, data-driven research. Traditional single-parameter research approaches proved inadequate for the complex, interdependent processes needed by Conti’s device architecture, prompting the adoption of a matrix-based experimental design and with high-throughput analysis. A partnership with NREL, and use of their facilities required, coordinated deposition, characterization, and optimization at labs on opposite sides of the country. This required the development of digital tools for real-time data collection and workflow management. Over the past two years, the team has completed 70+ experiments, fabricating 10,000+ solar cells, generating an extensive dataset, which through 3D visualization techniques was able to identify optimal parameters and understand dependencies.

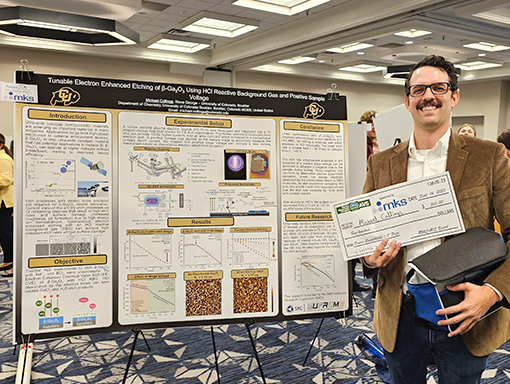

11:30 am - 12:10 pm | Electron Enhanced Chemical Vapor Etching (EE-CVE) of β-Ga2O3 with Hydrogen Chloride and Positive Sample Bias | Michael Collings, CU Boulder

Crystalline β-Ga2O3 is an ultra-wide band gap material with important applications for high power electronics. High precision etching is required for β-Ga2O3 device fabrication. Previous thermal atomic layer etching (ALE) attempts to etch β-Ga2O3 have not been successful. Plasma etching of β-Ga2O3 using Cl-containing gases is difficult for Ångstrom-level etching control and can leave surface damage. In this work, electron-enhanced chemical vapor etching (EE-CVE) of β-Ga2O3 is performed using an HCl reactive background gas (RBG) and positive bias applied to the sample stage.

The β-Ga2O3 film thickness was monitored using in situ spectroscopic ellipsometry. The etch rate is tunable from 1-50 Å/min by varying the stage voltage from 0 to +40 V, respectively. No etching was observed from electron exposures without the HCl RBG. Negligible etching was observed without a positive sample stage. The resulting increase in etch rate may be attributed to increased flux of reactive species (anions or radicals) caused by the positive DC bias applied during etching.

12:10 - 1:30 p.m. | Lunch and Vendor Exhibits

1:30 - 2:10 pm | The Quantum Revolution: Experimenters Were Also on the Barricades | Allan Franklin, CU Boulder

The names most associated with the history of quantum mechanics are Planck, Einstein, Bohr, Schrodinger, Heisenberg, and Pauli. They are all theoretical physicists. Yet experiment also played an important role. In this talk I will offer credit to some of them. I will discuss Millikan’s measurement of Planck’s constant, the experiment of Ellis and Wooster that established the continuous energy spectrum of electrons in β decay and led to Pauli’s neutrino hypothesis and Fermi’s theory of β decay, and the experiment of Wu and her collaborators that demonstrated the nonconservation of parity, or the violation of space reflection symmetry in the weak interactions.

2:10 - 2:50 pm | Lateral Thermal Atomic Layer Etching of 2D MoS2 | Janine Semple, CU Boulder

Atomic layer controlled etching of 2D MoS2 crystalline layers is important for the fabrication of MoS2 channel transistors. Individual 2D MoS2 layers must be removed to reduce MoS2 multilayers to MoS2 bilayers and monolayers. Removal of individual MoS2 layers requires lateral etching in the 2D plane of each MoS2 layer. In this study, the lateral etching of 2D MoS2 crystalline layers was demonstrated using two sequential reactions for surface modification and volatile release of the modified layer. O3 was used for MoS2 oxidation and SOCl2 was used for the volatilization.

Studies were performed using high quality MoS2 bilayers on silicon coupons. A decrease in optical contrast of the MoS2 bilayer during MoS2 etching was visualized by optical microscopy. Etching was observed by AFM as triangular etch pits inside the 2D MoS2 domains and removal of MoS2 from the edge of 2D MoS2 domains. The triangular etch pits and the gaps between crystalline domains grew progressively versus number of etching cycles.

AFM images were consistent with lateral etching at step edges of the 2D MoS2 layer. Enlargement of triangular etch pits versus number of etching cycles was “inside-out” lateral etching. Loss of MoS2 from the edge of 2D MoS2 crystalline domains versus number of etching cycles was “outside-in” etching. These AFM collocation experiments determined that “inside-out” and “outside-in” lateral etching rates were equivalent at ~5 Å per etching cycle at 175°C.

2:50 - 3:30 pm | Surface and Interface Characterization of Fuel Cell and Electrolyzer Components: Challenges, Advances, Insights, and Best Practices | Svitlana Pylypenko, Colorado School of Mines

3:30 - 6:00 pm | Networking Hour, Vendor Exhibits, free snacks, beverages, and prizes!

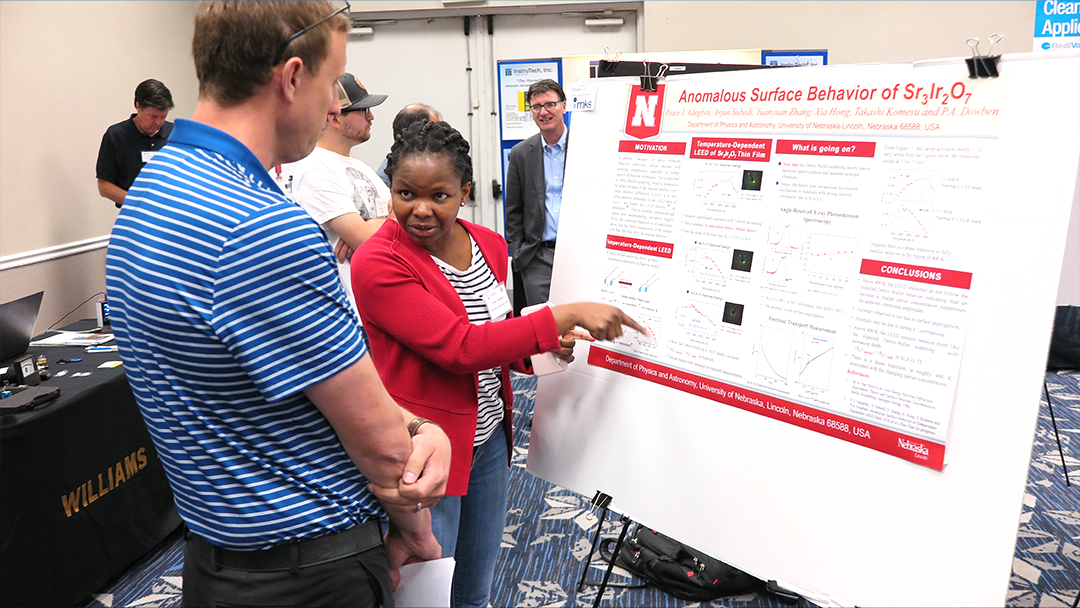

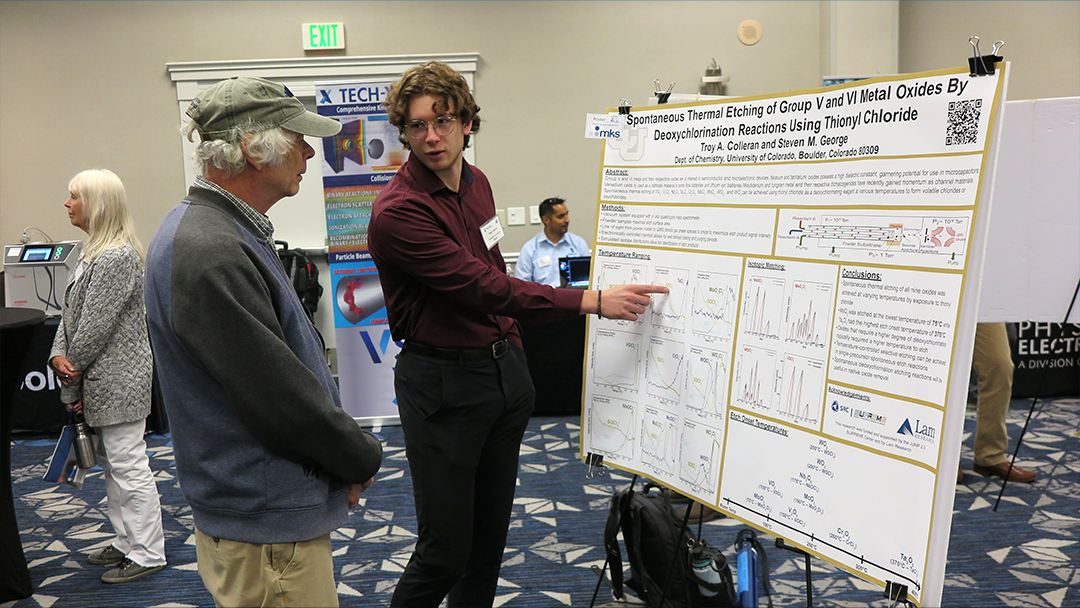

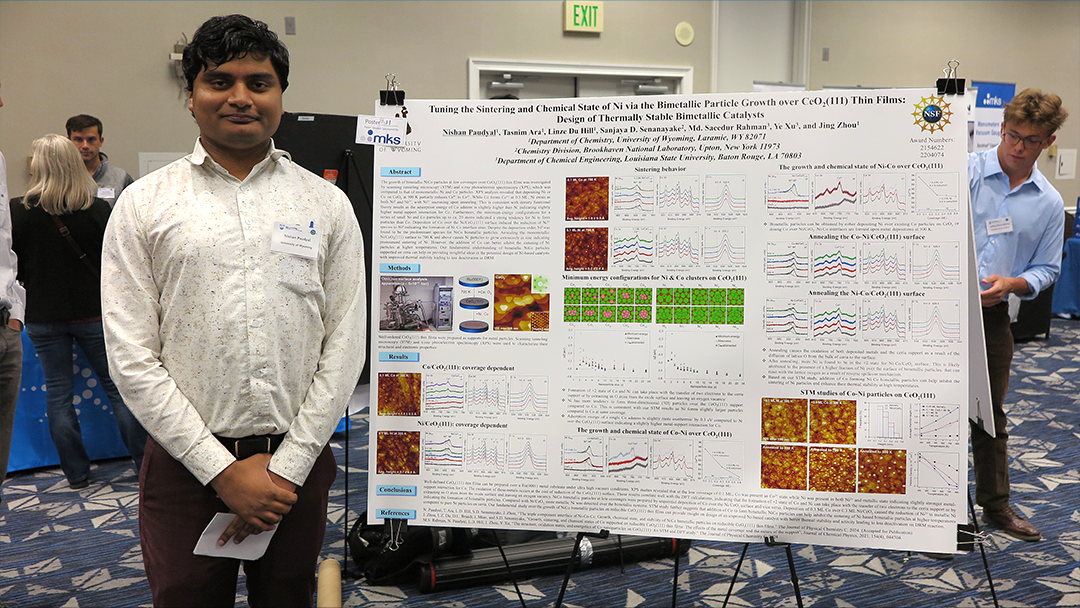

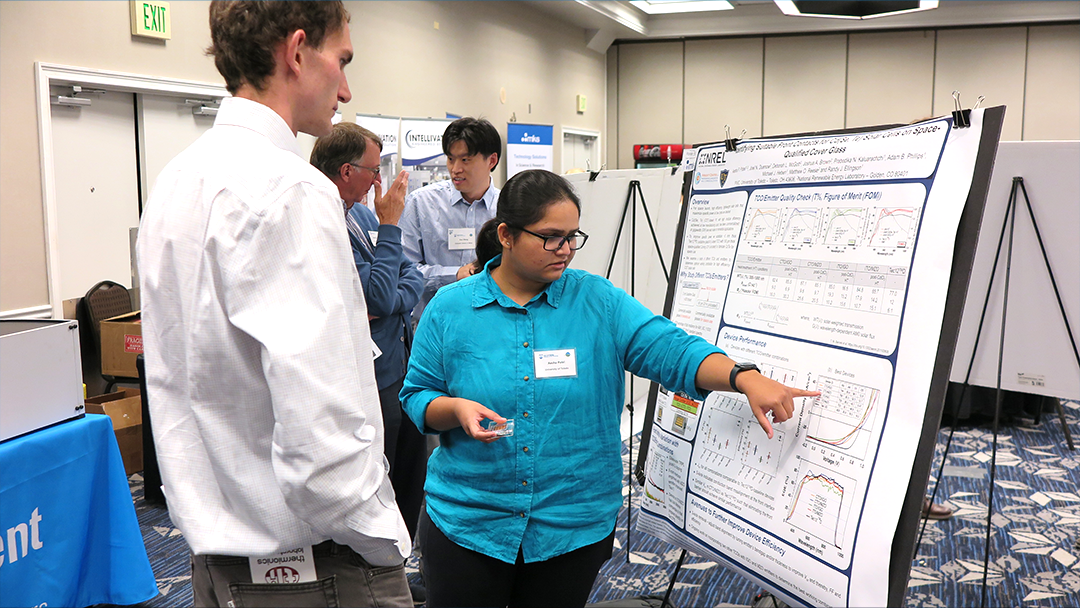

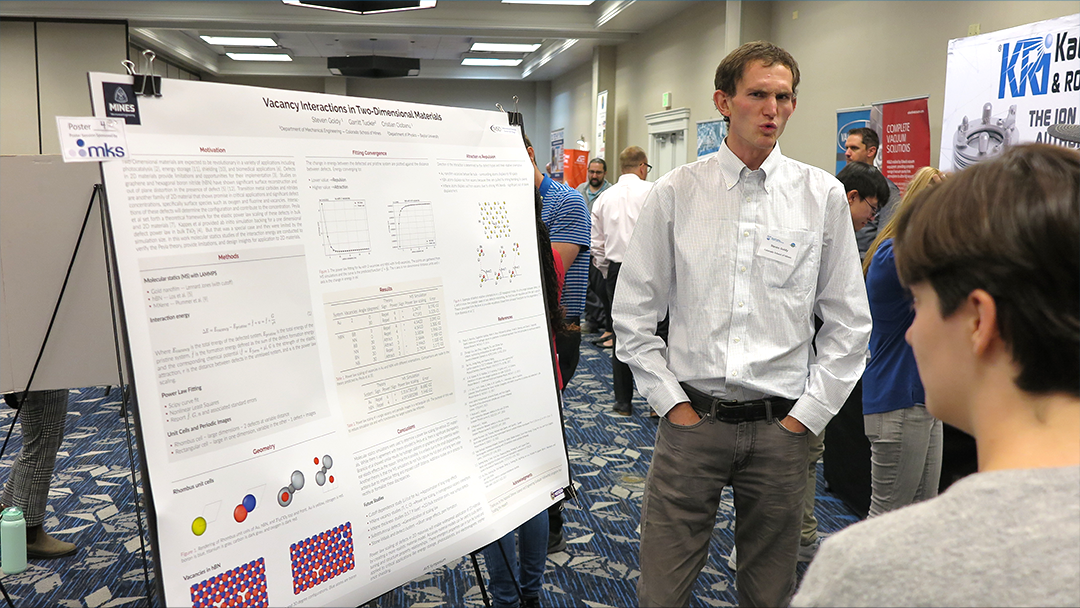

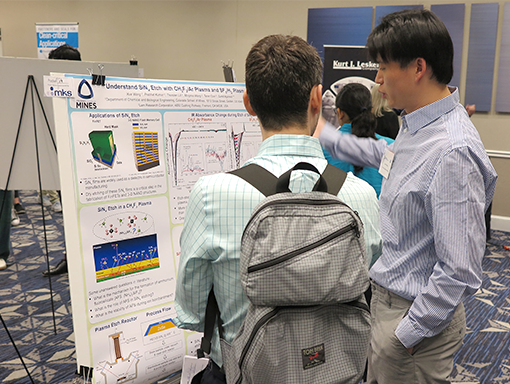

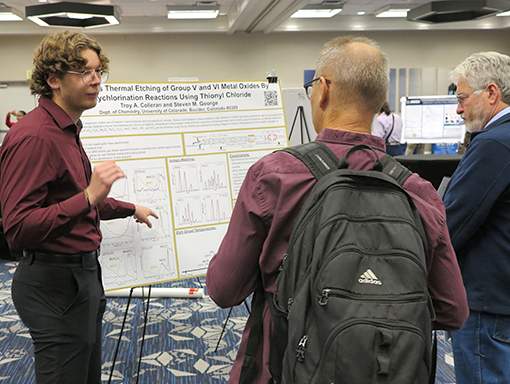

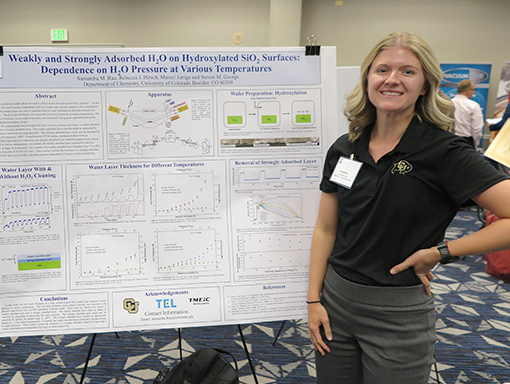

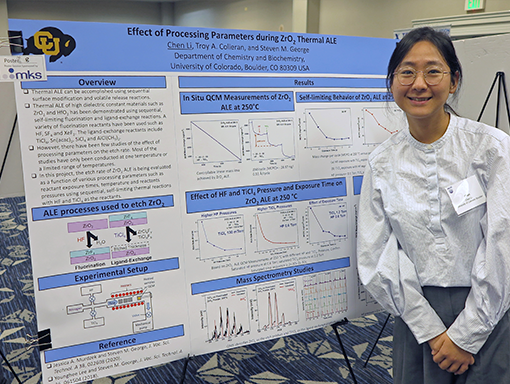

3:45 - 5:30 pm | Student Poster Session | Awards at 5:45 pm!

Free Tutorial presented by JR Gaines of KJ Lesker Co

Thursday, November 6 | 9:00 a.m. – 12:00 p.m. | Free Registration Required

Arrive at 8:45 a.m.

A Brief Introduction to Vacuum Science and System Design

Class time: 3 hours in the morning | This class is designed to introduce the student to basic concepts in vacuum technology and how they apply to system design and operation. Subjects covered include gas/solid and gas/gas interactions in vacuum, gas flow regimes, characteristics of gas composition at various molecular densities, vacuum pumps, pressure sensors, leak detection, vacuum hygiene, chamber manufacturing, system modeling, and the impact of fundamental design decisions and operating practices on vacuum system performance. It is intended for curious individuals who are new to vacuum without any formal training on the topic. It also provides a review of fundamentals for experienced vacuum technologists.

Student Poster Session: CALL FOR PAPERS — You could win up to $500!

Abstracts are requested for poster presentations. The poster session is concurrent with the afternoon happy hour and is fun opportunity to discuss your work. Posters will be judged and three poster prizes totaling $1,000 dollars will be awarded ($500, $300, and $200 for top three posters) plus free door prizes and student travel assistance is available.

To submit an abstract, please download the abstract template, email it to abstracts@rmcavs.org or by clicking on the submit abstracts button below, and register for free. Submit your abstract on or before the deadline of November 2, 2025. Maximum poster size is 48 inches wide by 36 inches tall.

Free Registration

Symposium, Vendor Exhibit, and Poster Session are all free and include lunch. Free registration required.

Student Awards Sponsored by MKS!

Student Awards will be presented for best posters.

2025 poster prizes are sponsored by MKS.

SPONSORSHIP

The Rocky Mountain Chapter of AVS welcomes you to support our activities — check out the benefits of sponsorship!

HOTEL INFORMATION

Please reserve your room using our group rate

Help the Rocky Mountain Chapter contain the costs of our Symposium by staying in rooms from our block at:

DoubleTree by Hilton Hotel – Westminster

8773 Yates Drive, Westminster, CO 80031-3680

The Rocky Mountain Chapter is required to pay to the DoubleTree hotel a penalty for non-used rooms in the RMAVS block. Failure to meet our requirements could noticeably increase the cost of putting on our event.

Group Rate $125 Available Tuesday Nov 4- Friday Nov 7 –– Book by Nov 1, 2025

Rooms from the room block are a good deal. The Rocky Mountain Chapter room rate is $125, much reduced over the comparable room/rate available from the hotel’s website.

Booking

- Call 303-427-4000, ask to get transfered to Sales, and then mention the group code AVS and group name: American Vacuum Society — Rocky Mountain Chapter

- Online at Westminster DoubleTree Hotel with AVS Group Rate

- Any questions? Please email Anastasia Rogers, Sales and Catering Coordinator, DoubleTree by Hilton Denver-Westminster at Anastasia.Rogers@Hilton.com